1-ton electric remote control tool carrier with excellent space mobility (iPTC 100)

- Mobility to facilitate work in tight spaces: triad track system

- Zero-emission for indoor operation: Dual power electric system

- Ensure safety for small equipment operators: wireless remote control

- Power station for various tools: hydraulic, pneumatic, electric power

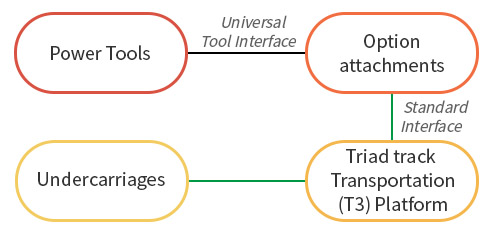

By providing a modular structure and a standard interface, customers can configure their equipment to suit their needs, and business partners can supply workstations or power tools to standard interfaces to implement the most efficient tool carriers.

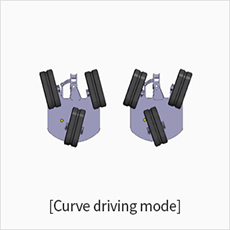

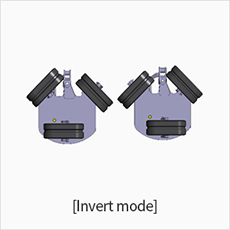

Triad track system: 3 tracks can be driven and steered independently

omni-directional direction movement, in situ rotation, step and stairway travel

0.8m door pass, 10-person elevator ride

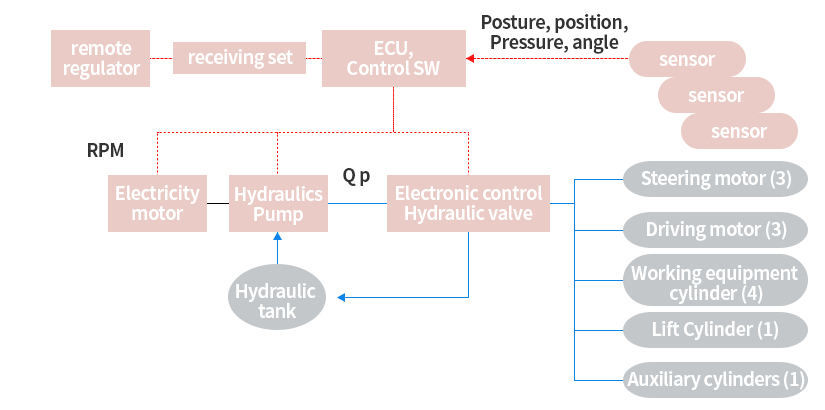

Wireless remote control

Operate equipment remotely for operator safety using wireless remote control. Use hydraulic control valve for remote control of hydraulic system. Providing a service platform

Dual power electric power system

Use battery power when moving, can move for up to 1 hour.

under carriages

case

| Power Tools | Opiton Attachments | Undercarriages |

|---|---|---|

| Hydraulic Electricity Pneumatics |

Excavators fork lift lift Robot arm Sprinkler |

Low Track Ls (~ 5kmh) High Speed Track HS (5 ~ 10kmh) Wheels Y-shaped rear |

| Specifications | unit | iPTC 100 | iPTC 120 | iPTC 160 | iPTC 200 | |

|---|---|---|---|---|---|---|

| Equipment Weight | kg | 980 | 1200 | 1600 | 2100 | |

| Equipment Width | mm | 750 | 750 | 780 | 780 | |

| Equipment Height | ||||||

| Main Body | mm | 970 | 1100 | 1300 | 1500 | |

| Working Device | mm | 1800 | 2000 | 2300 | 2500 | |

| Power | kW | 12 | 18 | 24 | 30 | |

| Lifting Force | kg | 200 | 250 | 300 | 400 | |

| Equipment Noise | dB | 90 | 90 | 87 | 87 | |

| Speed | Km/h | 4.0 | 4.0 | 4.0 | 4.0 | |

| Hydraulic System Pressure | bar | 220 | 220 | 250 | 250 | |

| Pump Maximum Flow | lpm | 30 | 35 | 45 | 50 | |

| Battery Capacity | kwh | 6 | 8 | 10 | 12 | |

| Battery Travel Time | hr | 1.5 | 1.5 | 1.5 | 1.5 | |

Triad Track Transportation (T3) System

- Omni-directional steering

- Take a ten-person elevator

- Width 800mm through door

- 30 degree slope, moving stairs

- Rotate body within 600mm radius

- 4m high work stability

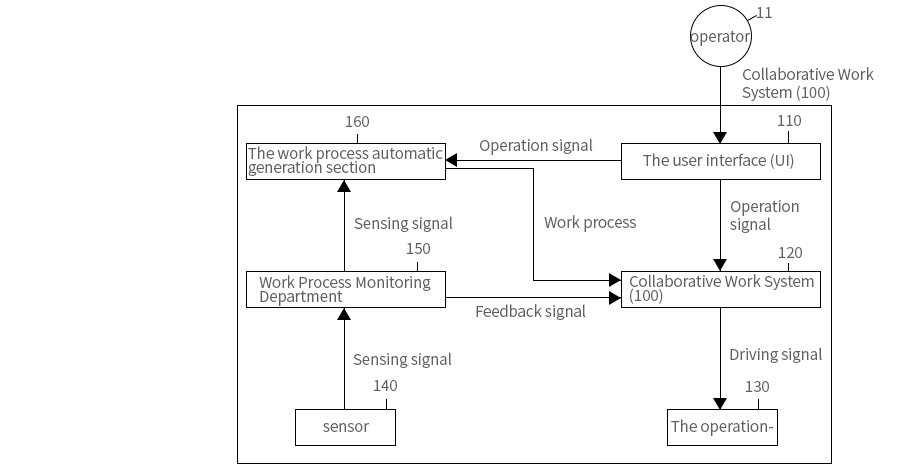

Autonomous Control based on Work Pattern

- Saving the operator's work pattern and creating the optimal working device and driving / steering simultaneous control algorithm accordingly

- Learning support system that novice driver can easily drive, learn function of expert and repeat

- Automated / semi-automated process control for real-time response to external environmental changes occurring under a given standard task

- Autonomous operation function against communication delay in network-based real-time control required by 4th industrial revolution model

Dual Electric Power Supply System

- Use plug-in power for AC 3-phase 380V power supply in normal operation

- Apply 48V motor and battery to Mild hybrid vehicle standard

- Applied AC flow motors on price, hazardous material environment usability, maintenance convenience

- Use 48V Lithium battery power when moving, carry around 1 hour or carry out light load

- If the business is useful, use the battery as an energy buffer: provide additional power for peak workload, save energy for low workload

- Battery charging time: 4 hr (during 4 hr working hour)

under carriages

case

| Power Tools | Opiton Attachments | Undercarriages |

|---|---|---|

Hydraulics Electricity pneumatic |

Excavators Fork Lift Lift Robot Arm Sprinkling |

Low Track Ls (~ 5kmh) High Speed Track HS (5 ~ 10kmh) Wheels Y-Shaped Rear |

ISCHUS Co. Ltd.

Representation : Jongmin Kang

Address : 8-108, 156 Gajeongbuk-ro, Yuseong-gu, Daejeon Metropolitan City, 34103

Company Registration Number : 527-86-01094

Main Phone : +82-42-863-7063

Phone : +82-10-8537-7063

Email: jongmin.kaang@gmail.com