Customer needs and technical solutions

- Use plug-in power for AC 3-phase 380V power supply in normal operation

- Apply 48V motor and battery to Mild hybrid vehicle standard

- Applied AC induction motor for price, hazardous material environment usability, maintenance convenience

- Using 48V Lithium battery power, carrying about an hour or moving lightly

- J1772 Level 2 battery charging time: 4 hr (during 4 hr working hour)

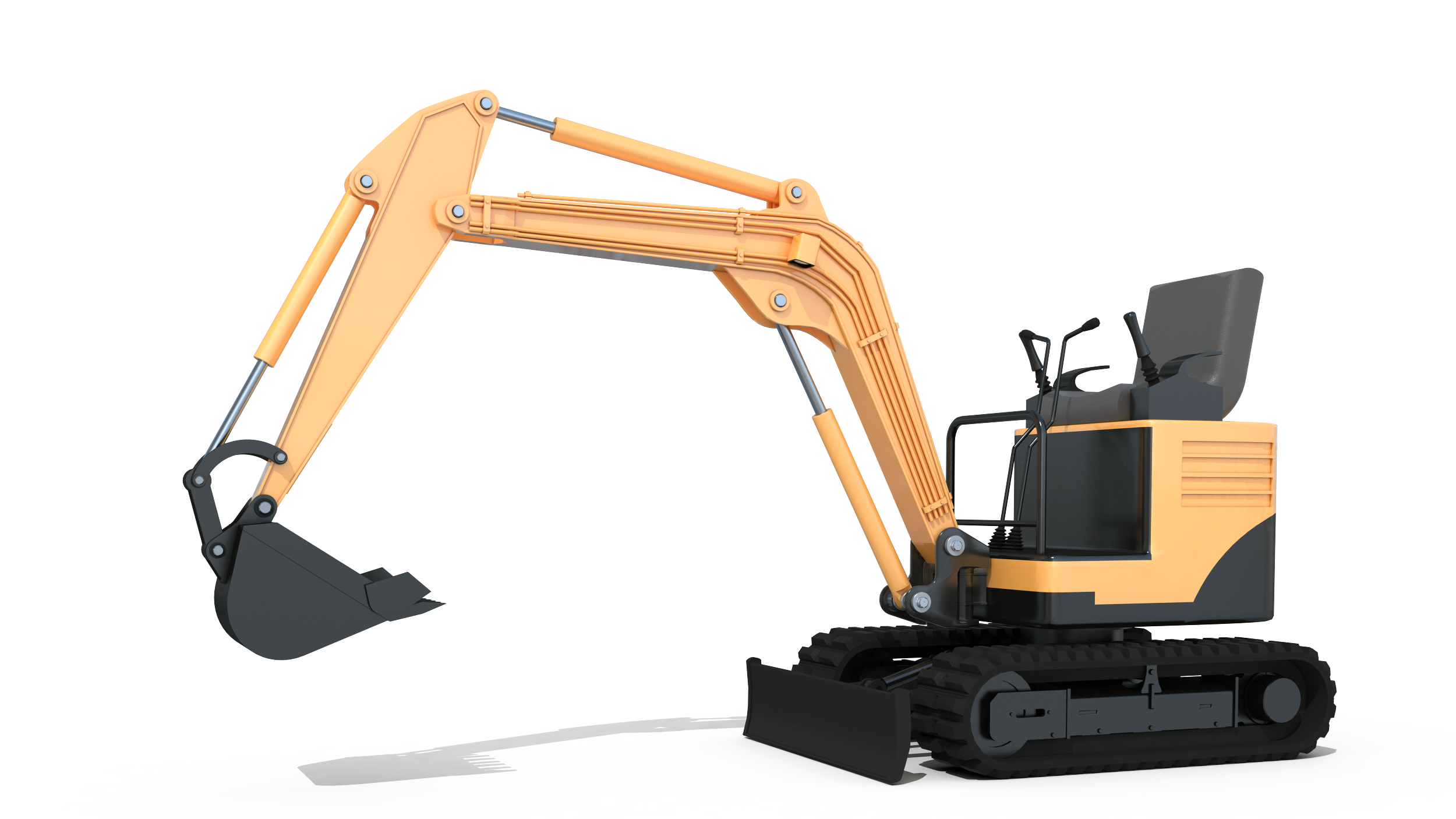

iPTC Product Development

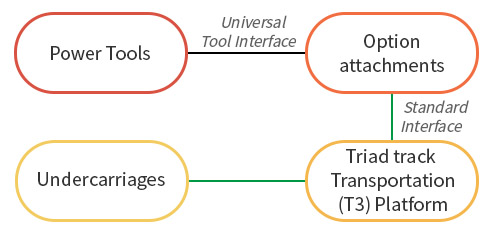

- Mobility to facilitate work in tight spaces: triad track system

- Zero-emission for indoor operation: Dual power electric system

- Ensure safety for small equipment operators: wireless remote control

- Power station for various tools: hydraulic, pneumatic, electric power

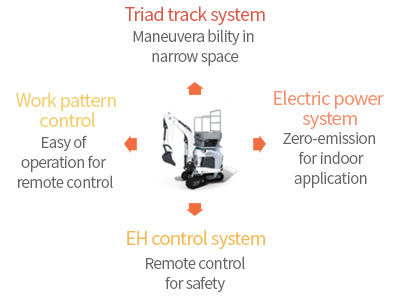

By providing a modular structure and a standard interface, customers can configure their equipment to suit their needs, and business partners can supply workstations or power tools to standard interfaces to implement the most efficient tool carriers.

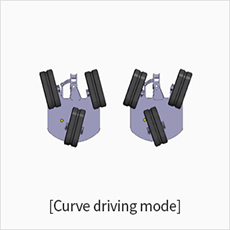

Triad track system: 3 tracks can be driven and steered independently Omni-directional directional movement, in-situ rotation, step and stairway travel

Pass through a 0.8m door, ride an elevator with eight passengers

Wireless remote control Operate equipment remotely using wireless remote control

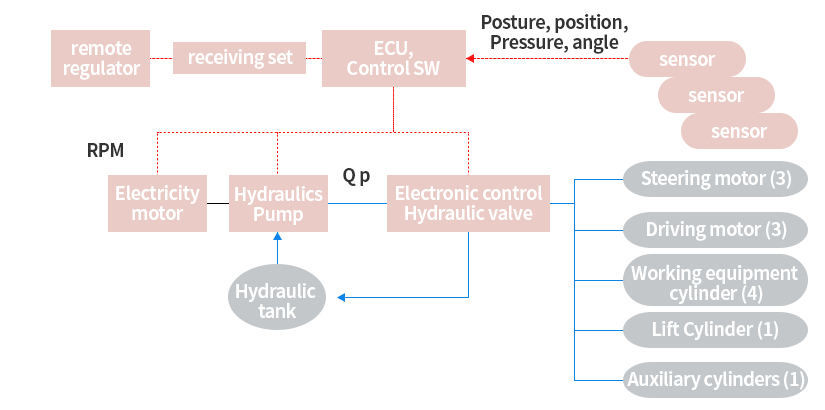

Hydraulics Use an electronically controlled hydraulic valve for remote control.

Dual power electric power system Use battery power when moving, can move up to 1 hour

Use of plug-in power when working, operation of working machine

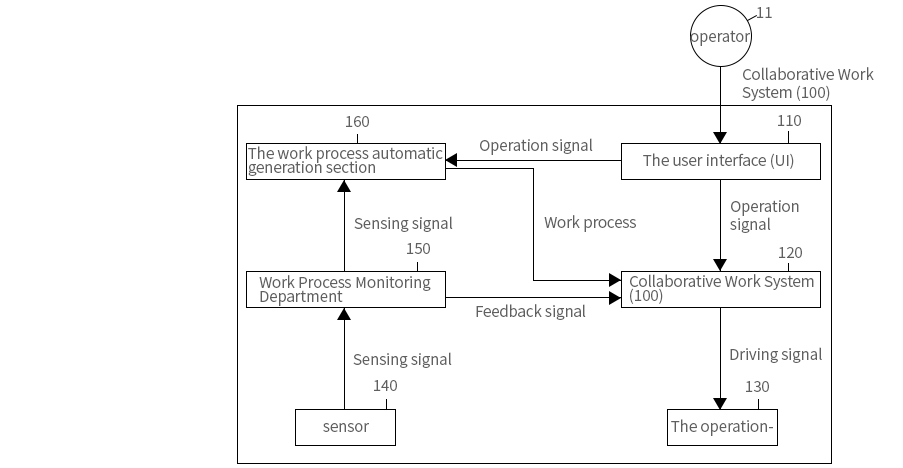

Work Pattern ControlSaving the work pattern of the skilled driver and accordingly generating the optimal working device and driving / steering simultaneous control algorithm,

a learning support system that novice drivers can easily drive and learn and repeat the functions of an expert,

automatic / semi-automatic process control that responds to changes in external environment occurring in a given standard work in real time,

Autonomous operation against network delay based on network-based real-time control required by 4th industrial revolution model

under carriagescase

| Power Tools | Opiton Attachments | Undercarriages |

|---|---|---|

| Hydraulics Electricity pneumatic |

Excavators fork lift lift Robot arm Sprinkler |

Low Track Ls (~ 5kmh) High Speed Track HS (5 ~ 10kmh) wheel Y-shaped rear wheel |